Digital Assistance Systems For Process Optimisation in Continuous Aluminium Casting

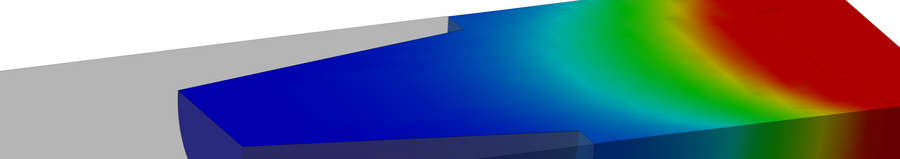

Aluminium as well as other light metals play a crucial role in achieving the climate targets since they are necessary for lightweight yet robust vehicle components. At the same time, their production and processing require high amounts of energy. However, the energy efficiency of these processes can be greatly improved by establishing cyber physical systems (CPS). Previously, many years of experience and resource-intensive experiments were required to find the right process parameters to produce high-quality components. Today, these trials can be carried out virtually using digital twins of production plants. This saves time, energy and avoids dangerous working conditions when testing new alloys or developing new processes.

Despite the available possibilities for creating digital twins, however, the light metals industry needs holistic digital assistance systems that can be adapted to innovative processes and new alloys. These assistance systems must be tailored to the needs of the users in order to achieve a real improvement in the processes.

This is exactly what the project opt1mus (Open Process Twin Minding the USer 1st) aims to achieve. The consortium led by the LKR Leichtmetallkompetenzzentrum Ranshofen and with the partners AIT Center for Technology Experience, HPI High Performance Industrietechnik and RISC Software (Logistics Informatics Department) is incorporating interdisciplinary, long-standing know-how as well as practical experience into the development of a human-friendly CPS using the example of horizontal continuous aluminium casting:

- In order to accurately predict the material quality of aluminium alloys in simulations, specially developed models are required that do justice to the physical properties of these alloys. The LKR Leichtmetallkompetenzzentrum Ranshofen has extensive experience along the entire process chain - from alloy development to casting and forming processes and prototyping to recycling - and accompanying simulations that can ensure just that. The company HPI High Performance Industrietechnik GmbH, a partner of the LKR, brings many years of experience in the construction of continuous casting plants.

- At the same time, in the sense of Industry 5.0, assistance systems are needed for foundry workers that make the process simpler and more efficient through intelligent suggestions directly at the Human Machine Interface (HMI) of the production unit. In addition, users should be given the opportunity to become "smarter" themselves over time through a comprehensible presentation of system suggestions. In order to be able to address an expanded, diversified user group in the future in the industrial environment, necessary factors in the design of the user experience (UX) are also being evaluated. The AIT Center for Technology Experience develops concepts for these interaction solutions in a user-centred design process.

- To provide well-founded support for the complex decision-making process of foundry workers, RISC Software GmbH, as a research institute for big data, artificial intelligence and machine learning, has been entrusted with the development of an advisor system.

Especially for Austria as an industrial location, the development of a flexible cyber-physical system is crucial in order to ensure the digitalisation of all production processes of supplier companies. For this purpose, the CPS developed in the opt1mus project will be made freely available as open-source software and attention will be paid to the possibility of adapting it to processes other than continuous casting. In this way, Austrian plant manufacturers and producers can develop innovations to reduce scrap and CO2 emissions and at the same time create people-friendly work through digital assistance.

Funded by the Federal Ministry for Climate Protection, Environment, Energy, Mobility, Innovation and Technology (BMK) and the Austrian Research Promotion Agency (FFG) as part of Production and Material 2022.