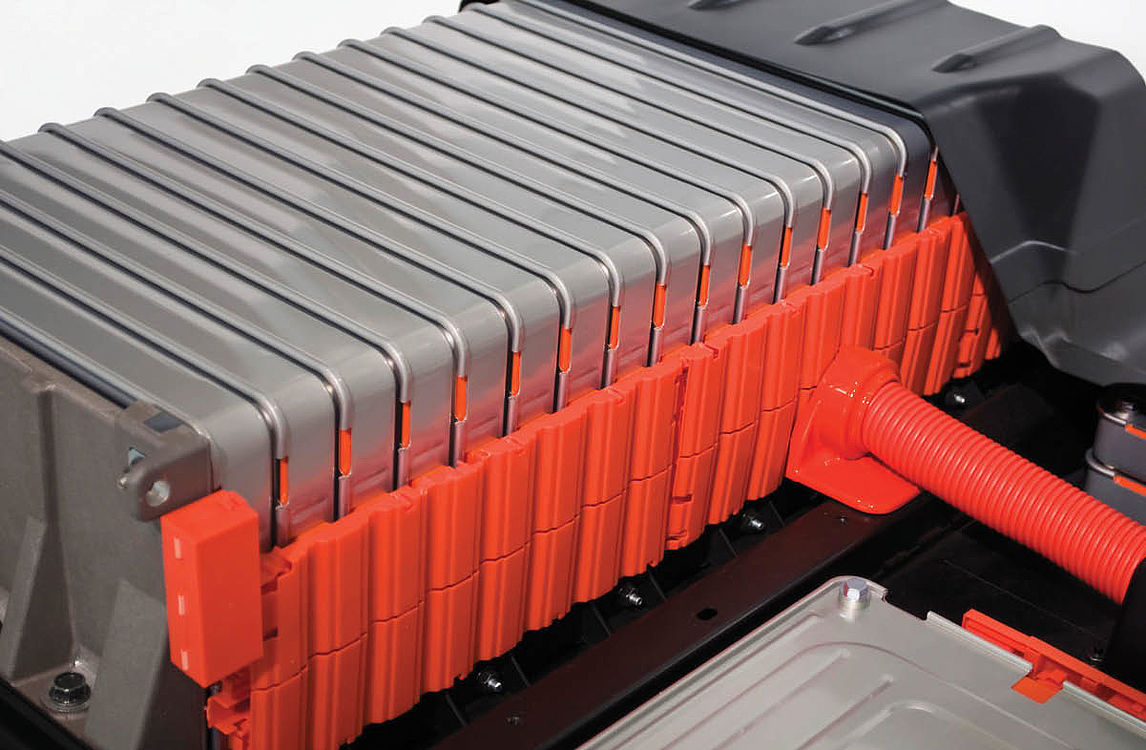

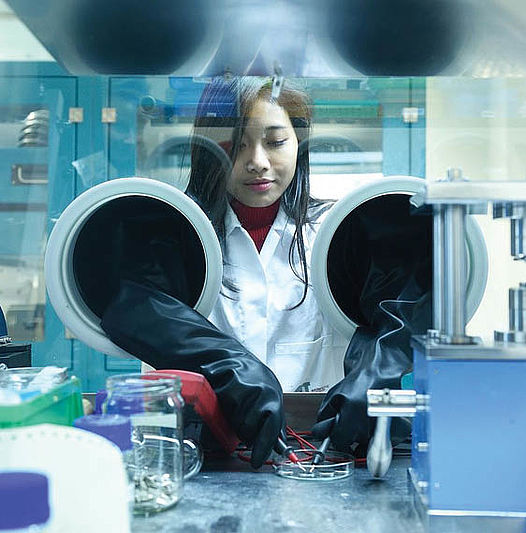

Discussions about electric cars usually focus on two aspects: cost and range. Both are directly linked to the heart of an electric car, namely the battery. An entire research focus at AIT is dedicated to this. Find out here how to make cars as efficient, cost-effective and safe as possible and why science is miles ahead of industry in this area.