Circular economy in construction – sustainable innovations at AIT

The construction industry is one of the largest energy consumers worldwide – yet it holds enormous potential for a sustainable future. The Austrian Institute of Technology (AIT) is driving the transformation toward a circular economy in construction through innovative research projects and practical solutions. Together with partners from business, academia, and politics, we develop new concepts for resource-efficient and circular building.

Why Circular Economy in Construction?

Within the EU, the construction industry is responsible for nearly 40% of emissions and one-third of total waste. At the same time, only about 40% of construction waste is currently recycled or reused. Implementing a circular economy in the construction sector enables:

- Reduction of CO₂ emissions through resource-efficient building methods

- Optimization of material cycles by using recycled and bio-based construction materials

- Economic benefits through innovative business models and efficient use of secondary materials

- More durable buildings through sustainable planning and deconstruction concepts

Circular Technologies for a Sustainable Future

Which circular technologies have proven particularly effective, and how can they contribute to the revitalization of sites?

This is a frequently asked question – but there is no “one-size-fits-all” solution. Success depends on the specific site conditions and the existing building fabric.

Our approach encompasses three essential levels of circularity:

Our approach encompasses three essential levels of circularity:

- Energy Circularity – Efficient management of energy flows, including aspects such as logistics.

- Information Circularity – Leveraging data to optimize decision-making processes.

- Material Circularity – Creating closed material loops to minimize waste and use resources efficiently.

Our approach to circular economy in construction

At AIT, we work on concrete solutions for a sustainable construction industry. Our research focus includes:

- Design for Deconstruction – Planning buildings from the outset for future reuse

- Closing Material Loops – Reuse and recycling of construction materials

- Using Digital Technologies – Smart data management systems for efficient material handling

- Developing Circular Business Models – New approaches for a sustainable construction economy

Current acceptance and integration of circular practices in construction

In recent years, interest in circular construction concepts has increased. However, the use of secondary materials remains low, while the consumption of primary materials continues to rise. To boost the acceptance of circular concepts, bold action is needed.

- Expansion of Recycling Centers and specialized deconstruction companies

- Awareness and Training – Educational programs and certifications for all stakeholders in the construction industry

- Financing Models – Adapting financing and insurance to support circular projects

Science and Practice Hand in Hand – For Systemic Change Toward a Circular Economy in Construction

Collaboration between science and practice is essential to successfully anchor circular concepts in the construction industry. We rely on innovative approaches such as pop-up labs on construction sites and real-time simulations in the City Intelligence Lab to tackle the complex challenges of the circular economy. These interdisciplinary methods promote shared understanding and support well-informed decision-making.

European framework and regulatory developments

The European Union supports the transition to a circular economy through a range of measures:

- Circular Economy Action Plan – Promotes resource efficiency and decarbonization in the construction sector

- Waste Framework Directive (WFD) – Goal: 70% reuse of construction and demolition waste

- EPBD & EED – Decarbonization of the entire building stock by 2050

- Level(s) – A unified European assessment framework for sustainable buildings

- New Construction Products Regulation 2024 – Sustainability assessment of construction products

- Austria’s Circular Economy Strategy – National strategy to promote resource conservation and material efficiency in construction

- City of Vienna’s Circular Economy Strategy – Local initiatives for sustainable urban development and promotion of circular construction practices

Together for a Circular Economy in Construction

AIT is your partner for innovative solutions in sustainable construction. With interdisciplinary research approaches, advanced simulation methods, and practice-oriented projects, we work together with companies, municipalities, and the scientific community to shape the future of construction.

Cost-optimized design

Complex energy supply systems, the intersection of electricity and heat, e.g. through the use of heat pumps and the consideration of life cycle costs, make a manually created, cost-optimized design extremely complex and subject to high uncertainties. AIT uses tried and tested methods from industry and power plant technology to create cost-optimized overall solutions for buildings.

Innovative energy concepts

Complex thermal and electrical energy supply systems, the coupling of electricity and heat (e.g. heat pumps), decentralized energy generation and storage (e.g. photovoltaics and battery storage), taking life cycle costs into account, make cost-optimized planning particularly challenging. We draw on our extensive expertise in numerical optimization to solve this complex challenge and develop cost-optimized, individual overall solutions for buildings.

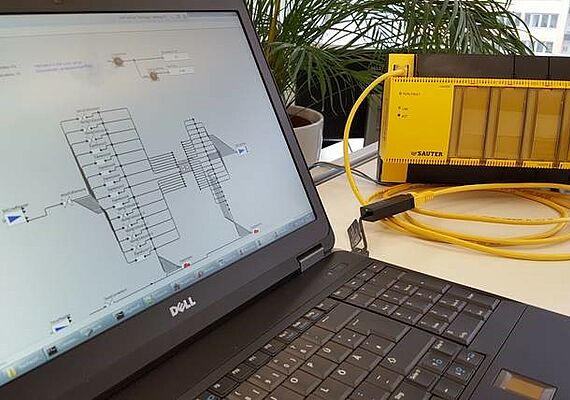

Controller-In-The-Loop CIL

High time pressure, frequent changes to planning requirements and the separation of the building services/MSR departments are the cause of many errors in the control strategies of HVAC systems. AIT's unique digital controller test bench allows control strategies for building automation systems to be tested at an early stage of the project, problems to be identified and rectified (rapid prototyping) and control loops to be improved. This significantly shortens commissioning times, reduces problems during operation, increases user satisfaction and reduces costs.

Monitoring and operational optimization

Methods of intelligent measurement data processing (data analytics) and modeling (machine learning and artificial intelligence) allow operators of buildings, systems and components to provide data-based proof of the efficiency of their systems, detect problems and faults at an early stage (e.g. for remote maintenance) and derive improvement measures during operation.